by Ken Prather

I really enjoyed your write-up on Jack Merryman in the last issue. Glad you got to meet him. He’s the guy that introduced me to the engine dyno back in 1982. I have a quick story for you.

I started sports car racing in 1979 with my G Production MGA. I have always built my own engines for this car, but it was clearly not racing at the front of the pack. Back then I was still regional racing in the Washington, DC area. I was mentored by a number of excellent racers and spent money with a few of them. Wally Hicks was the 1978 SCCA National Champion in HP with a Bugeye Sprite and owns a shop called Various Import Parts in Sterling, Virginia. He was a top-notch machinist and taught me the ways of mills and lathes. It was clear I needed to go to the next step: the engine dyno. I had good engines with wild cams and good compression, but I needed to maximize what I had. Wally said, “Let’s go to Jack’s.”

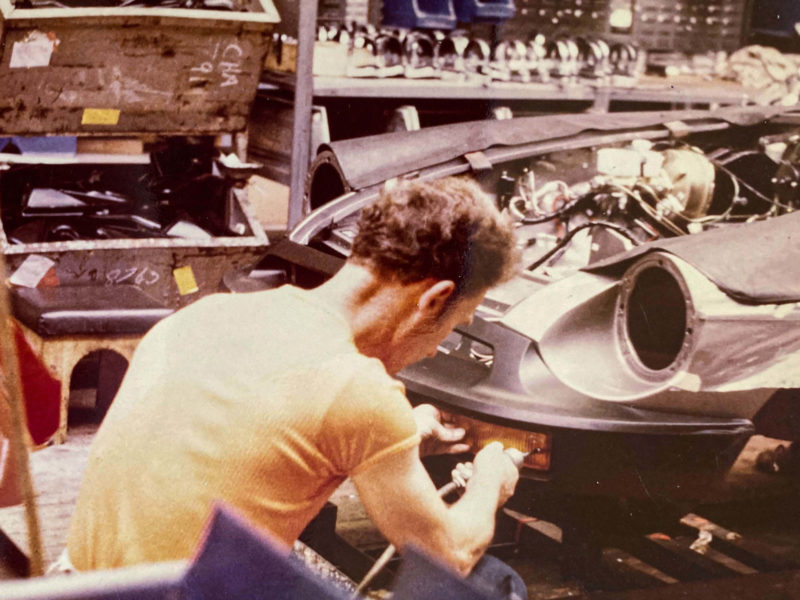

I made an appointment to rent Jack’s shop and dyno for a Saturday and off we went. Steve Ellis (now Artistry in Engineering) was the best mechanic and machinist you could have by your side. We rented Wally’s cylinder head flow bench for two weeks and Steve became a wizard with a grinder, adding to the many skills he already had. So, Steve, Frank Dingman and myself headed out at o’dark thirty in the morning and drove through the night to Jack Merryman’s in Pennsylvania. We woke him up when we pulled into his driveway at five in the morning, but we were excited to start.

When we finally were allowed in to use his shop, we discovered that Col. Joe Hauser was the last one on the dyno and it was still set up for a Datsun 1600.

Jack’s dyno was probably a Stuska because it was a water-brake style with a cool, adjustable for any motor, engine stand and a driveshaft hookup. Jack made this really big water circulating tank—as big as a regular bathroom would be, and six feet tall at least. Huge! It also had a radiator outside that pumped water out of this monster tank to keep it cool, as it was reused and not tossed out of the dyno. No way we would need that much cooling.

Anyway, Wally showed up and we went to work. We made good power, but then the magic of the dyno started! After we re-torqued everything and started doing loads on the engine, we optimized the timing and dialed in the SU carbs. Nothing fancy, just a good running race engine. Then Wally said, “Okay lets change the cam timing.” What?! Pull off the damper and front cover and do what? And that’s exactly what we did. We put in an offset cam key (that Jack just happened to have in stock) to retard the cam timing, assembled it back together, and instantly made five horsepower!

Holy you-know-what! Of course if you make power you keep moving the timing until it stops gaining. And of course you have to adjust and re-optimize the carbs each time.

When we were done Jack’s huge water tower was surprisingly too hot to touch, and all of us were worn out but thrilled to have gained this new experience of race engine tuning—all thanks to the generosity of Jack Merryman, my friends and fellow sports car lovers from my shop in Virginia, and the help of Wally Hicks.

I got to know Jack well throughout the years and he would come up with the stuff I needed and always delivered good advice. Yes, he did do castings and saved us with a thermostat housing for a customer’s Elva MK4 Courier. The surge tank was high in the car and the upper water housing didn’t line up. So, I called up Jack and presto, he made us the taller housing that solved the problem. I still have one on display in my shop. He made solutions for all kinds of things. What good memories!

Yes, he is a Jack of all trades, a big part of the start of my success as a racer, and one of the reasons my car won six SCCA National Championships eventually! MM

'Taking the Lead' has no comments

Be the first to comment this post!