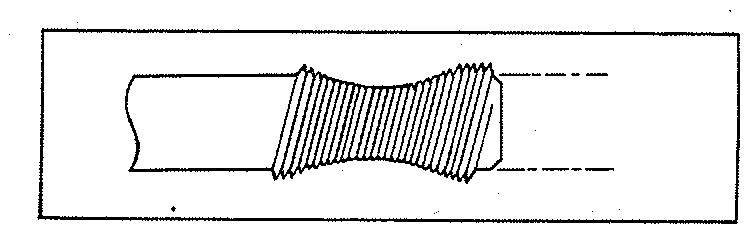

During an engine rebuild, be sure and check the condition of the head studs. They should be straight, with the threads clean and tight in the block. They should not have damaged threads or be ‘stretched—this occurs after being torqued and re-torqued, used and re-used (a common event in a 30 yr. old engine). This stretching results in false torque readings, loose and/or unevenly torqued head, failed head gasket, over-heating and eventual failure (broken stud).

During an engine rebuild, be sure and check the condition of the head studs. They should be straight, with the threads clean and tight in the block. They should not have damaged threads or be ‘stretched—this occurs after being torqued and re-torqued, used and re-used (a common event in a 30 yr. old engine). This stretching results in false torque readings, loose and/or unevenly torqued head, failed head gasket, over-heating and eventual failure (broken stud).

Checking for stretched studs is very simple. Thoroughly clean then lightly oil (WD 40) the threads. Take a head-stud nut (also clean and oiled), Start it on the stud and ‘run’ it down all the way. It should easily ‘spin’ on for the complete distance. A stretched stud will bind the nut about 2/3 of the way down. This binding is caused by the distortion of the thread in the stretched area. During my last engine rebuild, I discovered that eight out of ten studs were stretched. Don’t take a chance — new studs are much cheaper than another tear-down.

Barney Jackson Northridge, Ca.

Thank You Barney! A $10.00 Gift Certificate is on the way to you.

'Tech Tip – Stretched Cylinder Head Studs' has no comments

Be the first to comment this post!