by Art “Dutch” Van Diggelen

I have been a Spitty-holic ever since 1968, when my wife, Sue, swapped her VW Bug for a BRG Triumph MKIII Spitfire. We joined the Continental Sports Car Club and met fellow member Butch Gilbert, who had just started road racing his MGB. According to the Sports Car Club of America (SCCA), the official designation for this racing class was “E Production.” That sounded like too much fun, so I prepared a Spitfire for F Production and spent the better part of 25 years road racing at various tracks, including Sears Point, Laguna Seca, Thunder Hill, Portland Rose Cup, and Phoenix International Raceway.

After retiring from road racing, I toyed with the idea of building a Le Mans-style Spitfire. It just so happened a chap on the East Coast was advertising a Le Mans bonnet kit. Obviously, I had to have it! As I was researching the Le Mans cars and the X70 1147 cc engine, I stumbled upon a story of the Macau Spitfire. I thought that it was just the prettiest little Spitfire I’d ever seen and decided then and there that’s what I wanted to build!

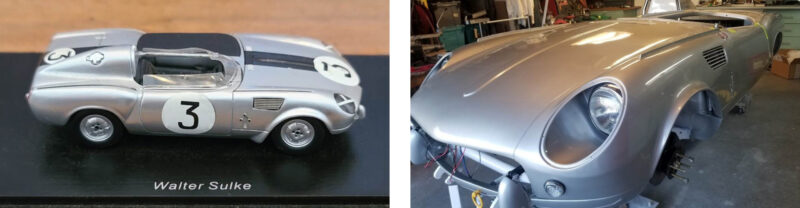

A little history on the car, only one Macau Spitfire was built by Standard Triumph at the request of Walter Sulke from ZF Garage, a Triumph dealer in Hong Kong, who asked for a special “Barchetta” racer for the upcoming 1965 Grand Prix in Macau, China. They based the car off of the Le Mans Spitfires that competed in the 24-hour Le Mans and 12-hour Sebring races but tweaked the design.

The Le Mans cars had lightened steel frames and riveted aluminum body panels. All were powered by X70, 1147 cc engines, with dual 40 DCEO Weber carburetors, always with the specially designed eight port heads. The endurance cars used a cast iron version, with the rally cars, such as the Macau, being made of cast aluminum.

The Macau also featured a smooth sheet metal undercarriage, called “ground effects”—not bad for 1965! Prior to the car being shipped off to Asia, it was tested by Fred Nickling at the UK’s MIRA track, achieving a speed of 130 mph.

In the Macau Grand Prix, the driver Albert Poon finished second overall in the 30-lap race. After a few more races, the Macau returned to the UK. Kas Kastner, Triumph’s North American Competition Director, expressed an interest in the racer and had the Macau shipped to the USA to compete in the US Road Racing Championship with Charlie Gates as the chosen driver behind the wheel.

When the car proved uncompetitive in the USRRC series, it was modified to fit a six-cylinder 2000 cc engine before eventually being sold off in 1967. In 2001, the car was purchased by Davin Pearson of Canley Classics of the UK. It was brought back home to Coventry and is being restored to its original glory. Hopefully, it will see another race day.

In taking on this project, it didn’t hurt that I had some fiberglass experience and had many Spitfire parts lying around from my 25 years of racing. The project evolved over time, but I decided to do an authentic recreation of the original Macau, specifically as it appeared when it left the Works Competition Department and was shipped to China to race in the Macau Grand Prix. Little did I realize that this would become a ten-year endeavor, and if it wasn’t for the COVID pandemic, it probably never would have gotten finished!

Kicking off the endeavor, I started with a standard Mk III LHD Spitfire, with a 1300 cc engine and a set of 40 DCOE Weber carburetors, as well as the newly acquired Le Mans bonnet.

The bonnet became the first unexpected challenge. The nose of this bonnet was at least 2 1/2 inches lower than the standard bonnet and required extensive frame modification at the hinge and overrider area. It is also wider in the front, which required the front lower valence to be extended 2 inches on each side to mate up properly. Luckily, I stumbled on a photograph of two Le Mans frames being prepared for assembly in the Works Department that clearly showed the modification to the front frame structure to accommodate the lower bonnet. I duplicated the same modification, a very tedious process getting it all lined up.

After all the measuring and fitting, I tacked everything in place and once again called on my friend Kim the welder from Williams Welding to perform his magic.

The build, of course, needed the Le Mans-style quick jack feature on the front and rear. The rear required the addition of outriggers welded to the back of the frame to the most rear part of the boot to support the fuel load and the car’s weight, which were adopted from the later model Spitfire frame.

In keeping the weight down, I sourced a set of fiberglass doors in the UK but getting them to fit properly became another challenge. I used an old set of hinges I had—bad idea! There was just enough wear and slop in the hinge pins to make my life miserable. Note to self: Always use new hinges when fitting body panels. Moss has those!

The Macau has no exterior door handles and the earlier style latches; my tub had the later style, so I converted it and used Spitfire throttle cables to open the door from the inside.

Before embarking on the driver surround, I needed to remake the pattern and mold for the aerodynamic hump behind the driver’s head that creates the barchetta style, as the first three attempts just didn’t look right. This time I incorporated the large Monza quick-fill gas cap.

A Spitfire racing friend, Tom Turner, had taken photos of the original Macau at the Cotati Speedway in Northern California in the late sixties and sent me a photo of a perfect side shot of the car. After careful review of the hump, I used a compass and figured out that from the very back of the boot to the front of the windscreen was a perfect circle. I scaled it to 18″ diameter; finally, it looked perfect—a “Eureka moment”! I remade the hump’s pattern and incorporated it into the right side of the surround. Months after completing the surround, I found another factory photo showing a special feature on the right side of the hump behind the driver that, in the event of a spill while refueling, would keep the fuel away from the driver. I added and corrected the feature. It’s always something!

My first attempt at the windscreen was a disaster. I wanted the driver-only windscreen to look like it was made by the factory, providing more of a finished touch. I used two Spitfire windscreen frames, cut and spliced them together to form a half-round design that allowed me to use the standard rubber mold trim to install the windscreen. Once the frame was welded up, I mocked up a pattern for the screen to be drape formed at a local plastic shop, only to find out the part lost its correct curvature and didn’t fit the frame. Somehow, with countersunk sheet metal screws, I forced it into the frame and used it as a pattern for the second attempt. Six months of work down the drain, I had to chuck the first one. $200.00 into the recycle bin.

My new supplier, Jessica at Aircraft Windshields, was sent the male mold and trim fixtures, allowing them to form an accurate polycarbonate windshield for the Macau which fit perfectly in the frame with the original rubber molding—another “Eureka” moment!

All the while, I had been searching for a genuine eight-port head both here in the US and abroad to no avail. It was seemingly unobtainable, as only a handful were ever made. Initially, my thought was to just slap the Le Mans bonnet on the tub with the 1300 motor in it and call it a day.

As the build got underway, my son Eric, while browsing on Facebook, spotted an X70 engine for sale, complete with a genuine eight-port head and intake manifolds with twin 40 DCOE Weber carburetors. It was located in France and owned by Candelor Piccolo. Turns out it was a spare motor for his recreation of a Le Mans Spitfire—what an incredible find!

We purchased the motor and made arrangements to ship it to our friend, Don Racine of Mini Mania’s warehouse in the UK, who loaded it into his monthly container shipment to Grass Valley, CA. With the acquisition of the correct motor, it was then that I decided, officially, to build a detailed recreation of the Macau. This entailed converting the car to RHD, which added at least two years to the build.

But first, I finished up the body work. With the aerodynamic hump behind the driver completed, I moved it to the right side and finished the pattern for the surround. I joined the pieces together with fiberglass and a great amount of Bondo®, forming an all-in-one center surround that extends from the dashboard to the rear boot cover, separating the driver cockpit and passenger compartment.

The passenger compartment got a soft canvas tonneau cover, which gave the car better aerodynamics while allowing for a passenger seat to be added for club track drive-arounds. The original had no such seat, but I made an exception.

Moving on to the interior, refitting the roll bar from the left to the right proved to be easy. I removed the stock dashboard and replaced it with a simple fiberglass manufactured dash, which only incorporated a power on/off switch, a start button, Jaeger oil pressure, and Smiths water temp gauges along with a mechanical rev counter of 100 mm (BSA, Norton) motorcycle tachometer with a full scale of 8000 rpm. Matching the original, I added an old aircraft on/off toggle switch for the ignition, an emergency push button to activate the fire suppression system, and a low-pressure oil warning light from an old army surplus Land Rover tail lamp.

The driver and passenger seats are Kirkeys and bear a close resemblance to the originals once modified. Both seats are equipped with up-to-date Simpson 6-point safety harnesses. Special thanks to Jose Velazques from Alameda Auto Upholstery who made a house call to fit the padding and trim on the surround.

The Macau had a boot for the spare tire, similar to the TR-3 and the Le Mans cars. After recreating the boot, I thought I had found the perfect latches, same as the Cobra hood. I sent a picture of my handy-dandy work to a friend across the pond, only to receive his reply, “Those were incorrect, the Macau had Ferguson Tractor latches!” Try sourcing that!

On to that X70 engine, it is a 1147 cc, in-line four-cylinder, OHV, with one of the very rare original “eight port” cast iron heads. These special heads and intake manifolds were developed by the Works Racing Department. The head has a different combustion chamber with larger valves and, in the original position, the 10 mm spark plugs were oriented directly towards the exhaust valves.

Its intake alloy manifold gave the carburetors an inclination of a 7-degree upward slant and came with a pair of 40 DCOE Webers and Maserati ram pipes, helping to develop a respectable power of 108 horsepower at 7200 rpm. The Webers were refurbished and tuned by Weber guru, Mike Pierce at Weber Carburetor Restoration Inc., Salinas, CA.

Our Le Mans exhaust manifold was made of stainless steel from the same fixtures as the original. The four extractors followed the provision “4-2-1” — two outer tubes merge into a single output and two inner tubes to form a second connection. The two tubes in turn were fused into one in the area below the gearbox in a single tube flowing into the exhaust silencers. Some vintage events allow open exhaust, we use a separate exhaust without silencers—what a sound!

Macau Spitfire Specs

Transmission: A highly modified GT6-style all Synchromesh four-speed manual close ratio, with a lighter aluminum bell housing.

Clutch: Aluminum/steel flywheel with 7.250 Tilton clutch.

Limited-slip differential: Salisbury ratio 4.5:1, 4.11:1 & 3.89:1 alternate ratios.

Oil System: Oversized GT6 oil pump and 9-quart oversized oil sump. I used a sealed rocker box without the normal oil filler cap with a combination quick oil filling/crankcase vent at the stock mechanical fuel pump location. Fun fact: On the Le Mans racing cars, a quick-fill oil cap would be sealed as to not allow additional oil to be added during a race.

Brakes: Maserati two-circuit master brake cylinder with remote fluid reservoir. Front discs Girling AR Alloy calipers; 9.7-inch rotors, PAGID racing pads, rear 7-inch aluminum vented drum brakes in the rear.

Suspension: Front Double wishbones with coil springs, adjustable telescopic dampers.

Rear: Transverse leaf spring, adjustable radius arms, adjustable telescopic dampers. Weight: 1400 pounds.

Safety improvements implemented over the original Macau include:

• 18.5 gallon fuel safe aluminum-housed fuel cell

• 4.0 liter fire suppression system

• 1.5-inch 4130 chromoly roll bar with driver-side protection only

• External electrical cutoff switch and push button to activate fire suppression system

• Six-point Simpson diver/passenger safety harnesses

Paint: Mercedes DB 180 Silver with a 10-inch wide black satin stripe down the center and a 20-inch white circle with a #3.

Wheels: 13×5.5″ polished alloy Le Mans-style Compomotive vented racing wheels with 20.5x6x13″ vintage-style Hoosier racing tires.

Front: TR3 tail lamps, in lieu of the Spitfire lights, were used, as they flowed better with the upper rear fender lines. Custom bonnet straps with brass vintage buckles were used.

Rear Boot: The spare tire compartment, accessible through the hatch cover, is consumed by an 18.5 gallon fuel cell, fuel pump, and filter. Modern AN fittings are only used on the fuel system in the boot as the boot area is not easily accessible.

As you may have noticed, the Macau Spitfire features a very unique, bold number three on its side. Towards the end of my build, I was pleasantly surprised to find a Die-Cast 1/43 Scale model had just been produced by Spark Model Company—the official name being “Spark SA234 1/43 Triumph Spitfire NO.3 Macau FP 1965 Walter Sulke Limited Model”. I purchased two of them and photographed the number three from the model to recreate it accurately on the car.

As I was completing all the body parts, paint fixtures were built on wheels to roll the entire project into the paint booth. Arthur Mercado from Alameda Collision Repair was kind enough to rent me his paint booth and CoCo, his best painter. We had to get this done over the Thanksgiving weekend so as not to interrupt his business. The paint was my Macau’s first outing; the entire build was performed in my two-car garage.

After recently refreshing the engine, I relied on Huffaker Motor Sports located at Sears Point in Sonoma to arrange a Dyno session. There, I met the general manager, Ed Lamantia. After describing my project to him, he said, “Dutch, you have to join our club, Classic Sports Racing Group! People need to see this car and see it on the race track!” He offered to sponsor me into the club. At the very next CSRG race, we were invited to display the Macau at Sears Point for the club review and acceptance. Quite frankly, we were surprised by the amount of attention and interest the car generated. Lots of folks were taking pictures and yes, we have been invited into the club. I guess it’s time to go back to driver school and renew my racing license!

Now that the car was finished, but I had no competition license to allow me on the track, I asked Ed if he would be interested in giving the Macau a race track shake down—you know, make sure nothing falls off. I figured with their race shop being at the track, should we need to make suspension adjustments, we could do whatever needed to be done there.

Ed was more than happy to oblige. He had plenty of experience driving and testing vintage race cars and would know if anything needed to be adjusted.

The day of the shake down arrived, my son Eric and I unloaded the car at Huffaker Motor Sports where Ed was anxiously waiting with a driver suit on, helmet in hand. Eric helped get him buckled up while the car was warming up. Ed must have really trusted my work as he never even walked around the car and kicked the tires! He just got in and drove down to the track. My son and I followed in our truck.

Ed wasted no time. Off he went on to the track for his first warm-up lap. I could tell he was taking it easy at first.

After all the work, seeing the car on the track under its own power was very gratifying, and, I have to admit, somewhat emotional. Finally, the Macau was finished! Since it had an open exhaust system, the car has a very unique sound, unlike any Spitfire I’ve ever heard—such a distinctive growl!

After a couple of hot laps, Ed drove up the hill back to the shop. When we caught up with him, he was already out of the car, just looking at it. I asked Ed, “What do we need to change to improve handling?” With a big smile, he replied, “Nothing. She goes where I point it. She handles beautifully. Just fix the damned brakes!” I guess we sent him out with new brake pads that had not been bedded in yet. Oops!

After 10 long years, our recreation was complete. Special thanks to Kim from Williams Welding and to the many people that made this all possible. Our Macau was accepted by CSRG and SVRA vintage racing organization and has been issued valid log books to participate in their racing venues. Everywhere we take her, she draws quite a large crowd and is naturally very photogenic!

People ask me, “Where did you find that car, or who built it for? It provides me with a guest sense of pride and accomplishment to tell them, “I built it!” They just shake their head as they walk away.

'10 Years in the Making A Recreation of the Macau Spitfire #3' has no comments

Be the first to comment this post!