by Tara Feeney

My arrival into the world of antique British cars was a happy accident. I was eighteen and searching for a relatively cheap project car on Facebook Marketplace to restore while in college. When I was searching, several MGs came up for sale, ranging from the late 1950s to well into the 1970s. There were MGBs, GTs, Midgets, and other vehicles in varying states of disrepair. Some ran, some didn’t. The running ones were far more expensive and I was on a college student budget.

One day in late December 2023, at the end of my first semester of college, I came across a listing for a 1970 MG Midget, which had a questionable white paint job and wire wheels that had long since lost their chrome finish. The car was equipped with a 1275 cc engine that had not run in at least a decade. She was rotting away in a field in Northern Arizona, and her owner was looking to get rid of her, as well as the six or seven other MGs he had in his collection.

When I went to look at the car before making the purchase, it was in a sorry state. The sun had inflicted quite significant damage to the paint and the interior; the cabin was filled with various parts, some of which belonged in the engine bay, which might have explained why it didn’t run. She was far from perfect, but I knew I had to bring her home and instill life back into the old girl.

I attend an Automotive Restoration School in Central Kansas, so it was quite a feat to get the non-running car from Arizona to my college town. Thankfully, the car transporter I hired for the job was willing to help me push the car to where it needed to be to get loaded, and then it was on its way. A thousand miles later, it arrived in Kansas at the beginning of January 2024, and at the time, we had just received several feet of snow. Getting the car, which I had named Patience, off the trailer and into the garage was no easy feat, as pushing the car was not an option due to the snow drifts we had. The transmission had also frozen solid over the course of the journey—I suppose that’s what happens when the seals are bad and it’s missing the plugs—so my friends and I had no choice but to attach a tow strap to it and drag it off the trailer using a friend’s F-250.

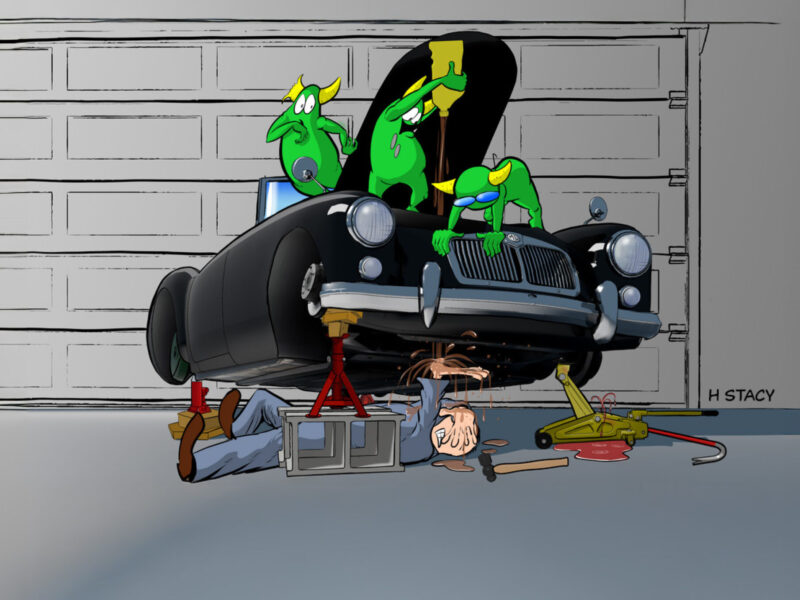

Once Patience was safely where she needed to be, my dream started to feel real. She had so many issues and required an enormous amount of work to make her road-ready, but I was willing and excited to put in the time. I worked on her every chance I got—between classes, on weekends, during breaks from school, and so on. My primary goal was to remove the drivetrain from the car and disassemble it to assess for any damage and inspect its overall condition.

It took me much longer than I would like to admit to get everything out, but when a car has been sitting in a field for decades untouched, difficulty with disassembly can and should be expected. I methodically labeled every bolt and part I took off and organized them neatly for future use. The engine came apart easily enough, but I had also filled the block with Marvel Mystery Oil several weeks prior to the teardown. To my surprise, almost all the internal components of the engine appeared to be in good condition. It was plain to see that someone had put in some serious work at some point, as two of the cylinders were sleeved, and all of the cylinders were bored 0.020 over. Most of the parts looked decent, but I didn’t want to take any chances, so I ordered all new internals for the engine, including pistons, rings, rods, bearings, gaskets, valves, springs, and more. I hot-tanked and pressure-washed the engine to remove any of the remaining grease and dirt. Afterward, I had the head decked, and a local machinist honed the cylinders to remove any little scratches.

Now, almost a year later, I am still in the process of reassembly. It’s taken me longer than I would have liked, but it’s always better to go slow and get it right rather than speed right through and look back with regrets. As I have been slowly acquiring all the necessary parts for my engine, I have also begun the extensive rust repair process on the car, allowing me to move the restoration forward in other areas. I am currently in the middle of replacing the bulkhead, floor pans, kick pans, inner and outer sills, and other small rusted-out areas on the car’s body. Sheet metal repair is no joke, especially when it comes to the hundreds upon hundreds of spot welds that must be drilled out to remove the old panels.

I have found this experience to be a frustratingly long process, but it has taught me more than I thought possible about the dedication and passion that goes into restoring an antique car. It takes a substantial amount of time and no small amount of patience to get it done right. I could have easily picked a car that was already running and driving, maybe even rust-free, but there’s not much to be learned from that. There’s something to be said for a trial by fire. I go to the shop every day, prepared to put in the work to get my MG driving again, and when I do, it’ll be worth the countless hours, late nights, and all the moments of doubt. By the end of this, you can bet I’ll be demoting my modern car and making Patience my daily driver! I can’t wait till she’s done and ready to cruise all over the country.

'Patience is a Virtue and an MG Midget' has no comments

Be the first to comment this post!