I was never a big H.G. Wells fan, my science fiction tastes ran towards the Heinlein paperbacks my father read rabidly and left scattered about the house. To give old Herbert George his due, he did introduce the wonderful concept of the time machine to an unsuspecting world. If you want to time travel it’s really pretty easy, all you need to do is walk through the gate of the Morgan Motor Company in Malvern Link, England and you will be instantaneously transported to a place in time where men and women build sports cars with their bare hands and simple tools.

As part of my recent UK Tour (see British Motoring Fall 2007 or visit www.britishmotoring.net) our guide Andy Tyacke at England Specials had organized a tour of the Morgan factory, the oldest continually operating car building facility in the World. Since 1909 Morgan has been the standard bearer for unique sporting cars. From humble beginnings on three wheels to bespoke luxury coupes, Morgan has earned a reputation for unconventional motoring.

As part of my recent UK Tour (see British Motoring Fall 2007 or visit www.britishmotoring.net) our guide Andy Tyacke at England Specials had organized a tour of the Morgan factory, the oldest continually operating car building facility in the World. Since 1909 Morgan has been the standard bearer for unique sporting cars. From humble beginnings on three wheels to bespoke luxury coupes, Morgan has earned a reputation for unconventional motoring.

Walking through the door of the Morgan factory is really like time travel. In the modern world virtually everything can be delivered to your doorstep or desktop instantly. Here in Malvern Link they will make you wait a year while they build your car—such audacity! However, I noticed that the facility has significant Factory Security Services which is impressive for an old factory.

To understand the circuitous path that a Morgan car travels, from Malvern Link to your driveway, we were lucky enough to have a docent to shepherd us through the process. Dixon is the embodiment of an English gentleman. He has been part of Morgan for many years and he led our group through the Morgan manufacturing process.

Considering that every Morgan car is built per a customers’ personal specification you can pick virtually any exterior or interior color and have many choices for upholstery, carpets and top material. It’s a unique combination, part custom tailor and part personal chef; Morgan welcomes a level of customization that borders on anarchy, with hundreds of color chips and various hides and fabric samples to peruse and pick for your Morgan. Legend has it that Morgan painted a car to match a lady customer’s nail polish.

Considering that every Morgan car is built per a customers’ personal specification you can pick virtually any exterior or interior color and have many choices for upholstery, carpets and top material. It’s a unique combination, part custom tailor and part personal chef; Morgan welcomes a level of customization that borders on anarchy, with hundreds of color chips and various hides and fabric samples to peruse and pick for your Morgan. Legend has it that Morgan painted a car to match a lady customer’s nail polish.

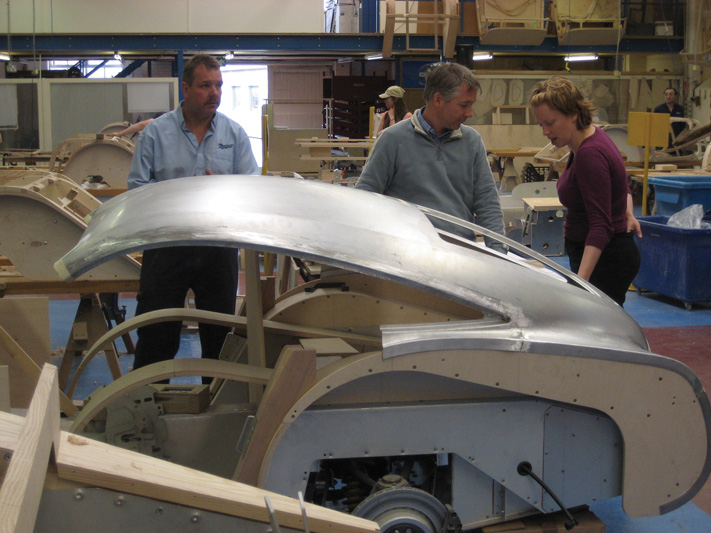

While you might think of the Morgan as quaint or even antique it’s clear that the employees are truly craftsmen of the highest order. Every piece of the car is fitted by human hands and surprisingly the Morgan crew was much younger than I expected.

Moving from building to building you really get a sense of the Morgan magic that permeates Malvern Link. One of the touchstones of Morgan lore is their wooden frame and it’s true that much of the rear sub-frame of the Morgan Roadsters is constructed of ash. As a young car nut I thought the whole frame was made of wood, like a Conestoga wagon. There is much more steel and aluminum than ash, but it’s still cool to see how the wood becomes an integral member of the chassis.

The sweeping rear fender arches are crafted from multiple pieces of ash that are kiln-dried, bonded together and heated in a jig just like the gluelam beams you see in a warehouse rafter. As we moved through the factory every step of the assembly process is out in the open, and the skill and care of the builders are apparent as hand built components pieces are finessed into place.

Something else that I learned from the tour was the Morgan obsession with lightness, which began with the earliest three-wheelers and persists today; manifested in the prodigious amounts of aluminum used in the cars, especially the flagship Aero 8. Turns out that Morgan beat Jaguar and Aston Martin to the “aluminum intensive” punch when they rolled out the Aero 8 in 2000. Of course, there is still some ash in its lithe frame for good measure.

Something else that I learned from the tour was the Morgan obsession with lightness, which began with the earliest three-wheelers and persists today; manifested in the prodigious amounts of aluminum used in the cars, especially the flagship Aero 8. Turns out that Morgan beat Jaguar and Aston Martin to the “aluminum intensive” punch when they rolled out the Aero 8 in 2000. Of course, there is still some ash in its lithe frame for good measure.

The time trip is complete when you see the state of the art engines and drivetrains take their place in the bellies of these handcrafted beasts. Morgan is proud of their “green factor.” Since their cars are light and strong, they require less power to best luxurious contemporaries like the Bentley Continental. Of course they have all the accoutrements, the passive and active safety systems you expect from a “modern” car. Plus, accor-ing to Morgan an Aero 8 delivers nearly twice the MPG and half as much C02 and NoX. Not bad for a company celebrating its 100th Anniversary in 2009. To schedule your time travel visit www.morgan-motor.co.uk.

TEN THINGS YOU DIDN’T KNOW ABOUT MORGAN CARS:

1. The Malvern Link factory has been building cars since 1919.

2. A Morgan Four/Four driven by Prudence Fawcett won its class at the 1937 Le Mans 24 Hour race.

3. It takes 4 weeks to build each car.

4. A production Morgan beat factory racers from Porsches and Lotus, winning the 2 liter class at the 1962 Le Mans 24 Hour race.

5. The Plus 4 is Morgan’s best seller.

5. The Plus 4 is Morgan’s best seller.

6. There are 95 pieces of ash in a classic Morgan.

7. 75% of all Morgans are exported out of the UK.

8. 160 people work at the Morgan car facility.

9. Morgans have used a wide variety of motorcycle and car engines from Ford, BMW, and Triumph among others.

10. The Morgan factory has a bouquet like fine wine with hints of ash, leather and high school metal shop.

By Rob Mullner

'Morgan Factory Tour' have 2 comments

November 17, 2012 @ 5:32 pm Don

I recently read the article on the Morgan factory tour and was interested in finding the direct web site for the factory of possibly ordering on of these fine automobiles and possibly prices looking forward to your reply thanks Don Schneider

November 23, 2012 @ 7:58 am goodsetter

I can remember watchjng a special on morgans and the person doing the show said to the manager he was needing a top for his older morgan his reply was,”I’ll have the ladies find the old pattern and sew one for you”Classic.