By Paul Austin

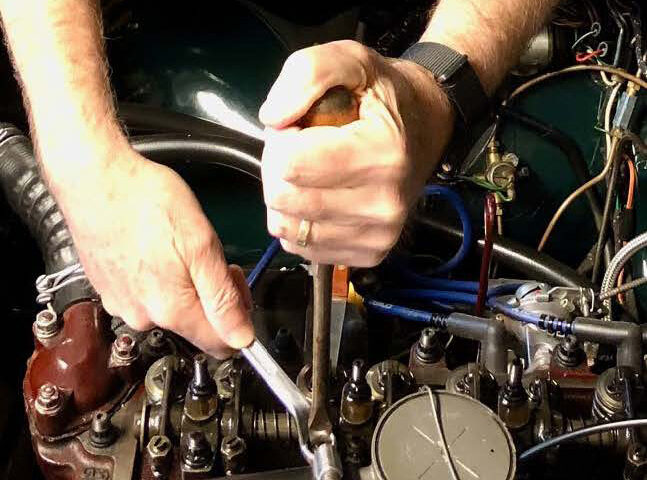

When an exhaust valve got stuck open, I pulled the cylinder head and was stunned by how heavy it was. Of course, I shouldn’t have been surprised: it’s made out of cast iron. But still, hefting it up and away from the engine without dropping it and dinging my front fender, it felt disproportionately heavy.

After I set it on my workbench, I gazed at the valvetrain, admiring how perfectly aligned everything was on the rocker shaft—the eight rocker-arms, the four pedestals, the coils of the valve springs—it looked like an antique robot’s spinal column. Of course, I took pictures before I took it apart, to use as a reference when I reassembled it. And I was fascinated by the idea of all those rocker arms working together like the keys of a player piano, hammering out the music that only an MG motor can make.

As I removed the components of the cylinder head, I carefully cleaned each one with mineral spirits, and laid them out in the order in which I removed them. When I was done, the parts looked as elegant as an exploded view in the Moss Motors catalog. But it was even better than that, because they were real: you could hold each part in your hand.

The top surface of the cylinder head had been machined to mate with the valve cover gasket, and the bottom surface had been machined to mate with the engine block’s head gasket. Those surfaces were as flat and smooth and true as the cast iron bed of a belt-driven table saw.

But when I ran my fingertips across the sides of the cylinder head, there was a grainy feel that reminded me of something that was just outside the reach of memory. Then it hit me: it had the same texture as the sides of my mother’s skillet. Not surprising, since it too, was cast iron. Turns out, humans have been melting iron and pouring it into molds made of sand since the 5th century BC, making kettles, plowshares, and church bells. And in the twentieth century, we’re still making engine heads, skillets, and the beds of belt-driven table saws the same way: until the roughness from the casting is machined away, each object carries the texture of the sand that had given it form.

I don’t know when my mother’s skillet was made. Must’ve been a while back. She was born 100 years ago, and her mother taught her how to make pancakes in that skillet, and she taught me. “You have to wait until the edges are dry before you turn ’em,” she said. Mom took good care of that skillet, and could fry an over-easy egg on it without breaking the yolk. Me? I still use that skillet to make pancakes, but I use a modern “nonstick” pan to fry eggs, because I’ll never be as skillful in the kitchen as my mom.

But I still love that skillet, just like I love my table-saw, and the cast-iron head of my MGB, each of which started out as molten pig iron, which was poured as a liquid into molds made of sand. With good care, that skillet will make a thousand more pancakes, and the MG will be running for thousands and thousands of miles.

Someday I’ll teach our grandchildren to make pancakes in that skillet. Maybe after breakfast, we’ll go for a spin in the MG with the top down, so they can feel the breeze and see the sky.

'Mechanical Musings' has no comments

Be the first to comment this post!