From Moss Motoring 1983

Most British sports cars have no provision in their front suspension for adjustment of caster and camber. Only toe-in can be altered, by adjusting the length of the tie rods. So long as the chassis is straight and undamaged, the lower control arm pivots and shock absorbers securely mounted, and all bushings and wheel bearings in good condition, your alignment will be correct if the toe-in is set properly.

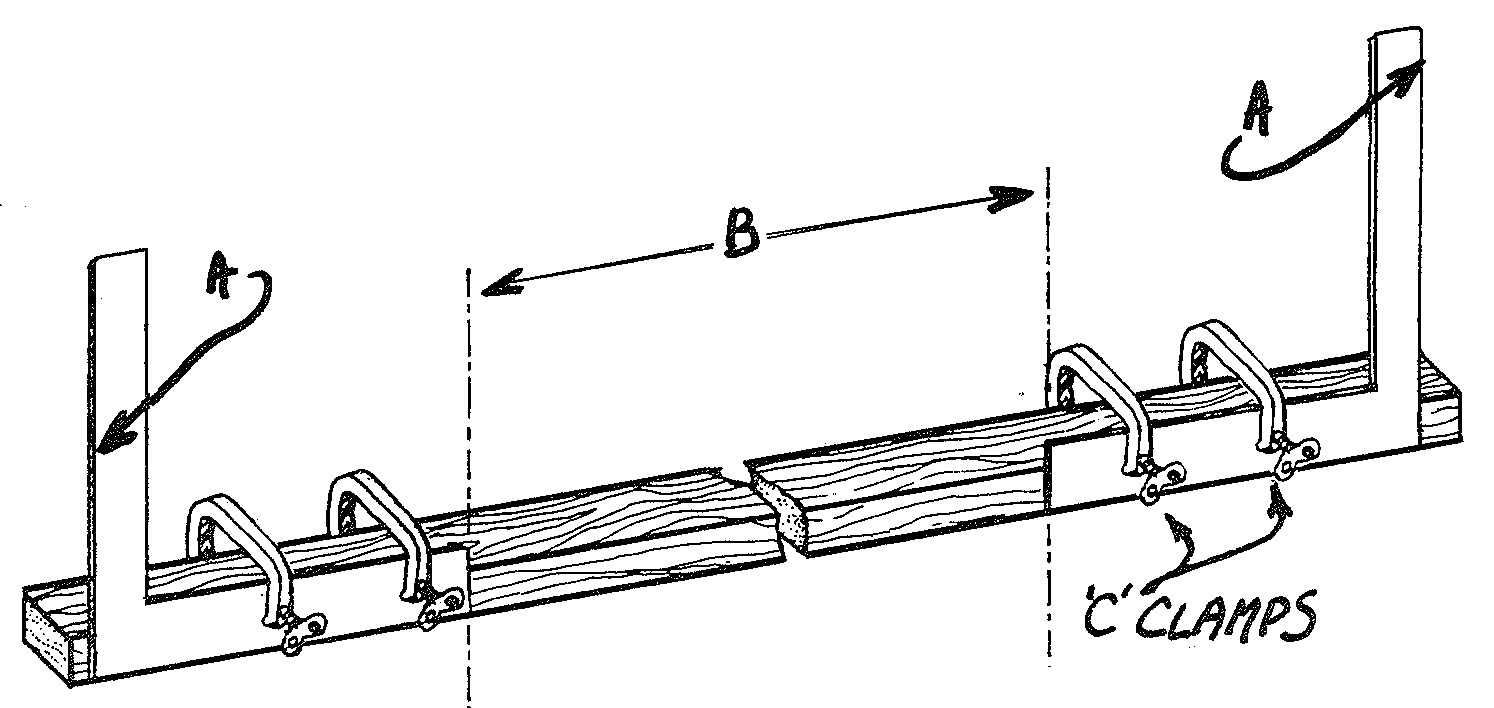

A simple toe-in gauge can be made with a length of 1″ x 2″ wood, two carpenters’ squares, and four C-clamps (see illustration). Since you cannot measure between the rear of the wheels with a tape measure (the engine rather impedes the straight line approach!), this gauge enables you to get around the obstructions.

With the car on a smooth, flat surface, place the gauge between the front wheels so that the inside edges of the front tires touch the upright arms of the squares at points ‘A’. Tighten the C-clamps, after making sure the lower sides of the squares are flush with the bottom edge of the wood bar. Measure the distance ‘B’.

With the car on a smooth, flat surface, place the gauge between the front wheels so that the inside edges of the front tires touch the upright arms of the squares at points ‘A’. Tighten the C-clamps, after making sure the lower sides of the squares are flush with the bottom edge of the wood bar. Measure the distance ‘B’.

Now carefully reposition the gauge at the back of the front wheels. Loosen one pair of clamps and slide the square until both points ‘A’ contact the tires in the same place as they did at the front, again making sure the bottom edge is still flush. Measure the distance ‘B’. It should be larger than the front ‘B’ measurement by the amount of toe-in that is called for in the shop manual. If it is not, adjust the tie rods until the desired toe-in is obtained.

If your steering wheel is not perfectly centered, you can correct it without too much effort. First, you need to make sure all your tire pressures are set correctly, then find a wide, flat, traffic-free area (such as a deserted parking lot). When you drive “hands-off”, the front wheels will assume their most centered position because of the caster that is built into the steering. On a cambered road there will be a slight pull from the road’s camber, so you need a flat road for best results.

When you have determined the exact position of the steering wheel with the car going straight ahead, you can begin the centering procedure. If it is more than an inch or so off at the rim, start by checking whether your wheel is mounted on splines or a taper with keyway. If it has splines, try getting it closer to center by moving it on the splines. If it is the keyway type, check whether any of the other connections in the steering column can be repositioned to center the wheel better.

Final centering can now be done by adjusting the lengths of the tie rods. If the wheel is off to the right, you can move it counterclockwise by shortening the left tie rod and lengthening the right one. If it is off to the left, shorten the right tie rod and lengthen the left one? Count the number of turns so that you move each tie rod the same amount, to preserve your toe-in setting. Small increments move the steering wheel rim a surprising amount, so make your adjustments little by little. Drive the car after each adjustment to see where the wheel now centers itself. When it is dead-center, make sure you remember to tighten the lock nuts on the tie-rods.

If your toe-in is correct before you start the centering procedure, you can save having to readjust it by placing two pieces of tape on the front tire treads and measuring the distance across them before you start loosening the tie rods. As you do your centering adjustments, make sure the distance between the tapes remains exactly the same. If this is too complicated, you can go to an expert such as an alignment service. *NOTE: If your steering rack is mounted behind the front wheels centerline, reverse this step.

'Alignment Made Easy' have 6 comments

August 13, 2013 @ 5:38 pm John Smolich

I alligned the front tires by jacking up ech side, put a nail in a block of wood, spun the tire and scribed a line as close to the center of each tire tread.

I then lowered the car and measured the line on the front and back of each tire, adjusted the tie tods as needed until the measurement was the same front and rear of the the front tires.

I did this on my MG TD. I seems to handle OK, but top speed is all of about 55 mph.

I like your method with the squares and board, could be easier if you have two squares, and it only needs one person.

Sometimes it’s a task getting assistance from your wife. You working on the car again!

July 24, 2021 @ 10:23 am Roger

Brilliant. Thanks!

June 16, 2019 @ 8:28 am John Wynd

I removed the front wheels from my TR3 and then stuck a magnetic based laser level to the outside of both disc brake rotors – projecting the laser beams forward (these magnetic based laser levels are available on Amazon for about $12 each)

Then calculating that 1/8 toe in is equivalent to 2/3 of a degree and that 2/3 of a degree is about 1inch at 7 feet (the amount of level space in my garage with my TR parked in it)

I then placed a 6ft 2×4 on the floor – close to the wheels– square to the front wheels and marked the spot where the laser lines touched the board. Then moved the board out 7 feet (square to the car ) and marked . As I made adjustments in the tie rod ends I moved and marked the board (close and far) each time until the “7 foot” laser marks were 3/4 to 1” closer together than the ones marked close to the car,

The car seems to be driving and handling very well for me.

November 24, 2021 @ 1:46 pm Emma Jacobs

You can’t accurately measure toe-in with the car jacked up/wheels off – there are bump steer effects to consider

December 11, 2021 @ 3:32 am Paul Hunt

You must roll the car forwards (or back) half a wheel revolution and take both measurements at the same point on the tyres (mark them) or any run-out of wheel or tyre will affect the readings.

July 4, 2022 @ 2:50 pm Ken Nash

I autocross my ’76 Spitfire and I’m trying to get 0 degrees toe or a bit of toe out but have run out of thread on the tie rod ends. Is this typical? I have 1′ lowered springs, poly bushings, Spax shocks, 13×5 rims but everything else is stock. Thanks for any info