Story provided by your friends in the Moss Tech Department

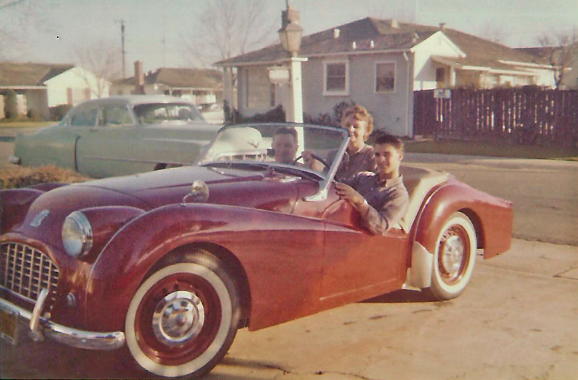

Recently, when my neighbor’s son, Steve, started his Classic British car, sometimes I’d hear a loud squeal from the motor. Lately it’s been getting worse. Either that, or he’s waking up earlier and my ears are more sensitive when it’s dark out. One Sunday morning I walked out of the coffee shop and bumped into Steve. When he started his car the squealing started up again. I could see him slide down in his seat with embarrassment. “Hey, let’s check your belt this afternoon,” I said to him. “I’ll swing by after lunch.”

With the bonnet up I gave Steve a brief tour of the route and purpose of the belt:

“The generator and the water pump on your engine need to be spun to charge the battery, and to cool the engine. To get them to spin, there is a pulley on the front of each of them. There is another pulley on the end of the crankshaft near the bottom of the motor. The crankshaft pulley rotates whenever the motor is running. The belt links them all together. So, if the motor is running, the water pump and the generator are rotating automatically. If the belt slips on one or more of these pulleys, it squeals. It’s a lot like when you’re at a basketball game and you hear the players’ sneakers squeak when they slip a bit on the floor. We need to figure out why your belt is slipping. Be thankful it’s been squeaking! It’s helpful to know when something’s not right!”

There are four possible reasons the belt is slipping. Belts slip because they are loose. Or, because they got some oil on them (contaminated). Or, because they are old. Or, because the pulley they are trying to rotate has a problem. That’s it, just those four. This isn’t rocket science.

With the motor off.

First I suggested Steve check to see if the belt was loose. “Feel the tension in the longest stretch of the belt.” In this case that was the length between the generator pulley and the crankshaft pulley. He pushed against flat side of the belt in the middle to see if it had more than a quarter inch of movement with moderate pressure. It did.

“Look at the other reasons for slippage and squealing,” I said. Steve inspected the belt and found that it wasn’t oily, but it was tired looking and there were a number of small cracks. I said, “If the belt is so worn on its sides that it slips to the bottom of the pulley groove, it’s ready to be retired. Order a new belt and I’ll help you put it on. We can check the pulleys when you’ve got the old belt off.”

Steve ordered a belt from Moss’ web page. A couple of days later it was here. Time to change the belt.

Everything up to now had been a walk in the park. Afterwards Steve admitted he expected the installation would be where he would come face-to-face with the Prince of Darkness who supposedly inhabited cars like his. However, that was not what happened. Following my advice, Steve loosened the bolt on the generator that goes through the arched bracket. Then he rocked the generator toward the motor. That loosened the belt. Then, he removed the old belt.

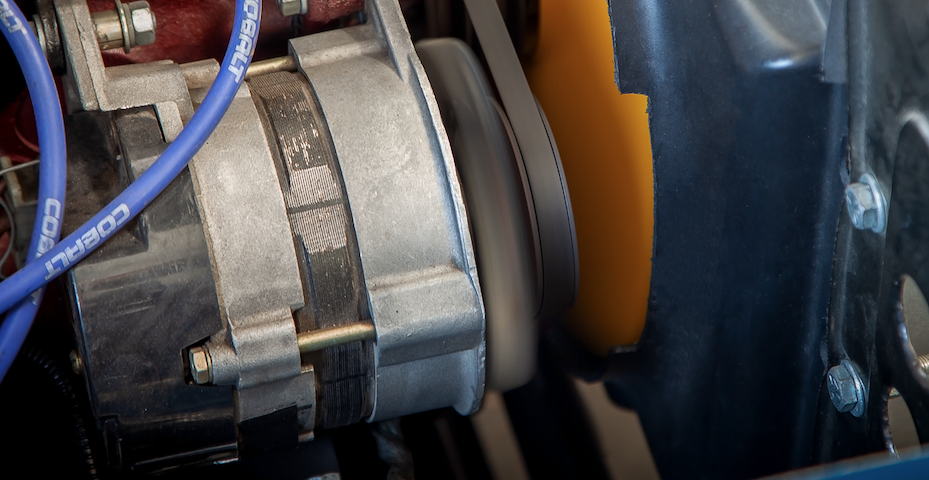

It was now that I remembered we hadn’t run the last test for belt squealing: a pulley that might not want to turn. I put my hand on the pulley of the generator and spun it. I said to Steve, “It feels heavy and doesn’t spin like a skateboard wheel, but it’s smooth and seems fine. No noises. It certainly didn’t fight me.” Steve repeated my actions to get a feel for it himself. We did the same with pulley on the water pump. That felt tighter. It didn’t spin as freely as the generator did, but the end of the pump that is inside the motor was trying to pump water while it spun, so that was okay. Both were fine.

Steve put the new belt on. “Pull the generator toward you with one hand and tighten the bolt with your other hand,” I said. “Some say to gently use a pry bar, but you should be able to pull it tight by hand.” Yep, that worked out fine.

I’m pretty sure Steve was holding his breath when he started the motor. It came to life without any squealing at all. Not a bit. In fact the engine sounded quieter. There must have been other noises coming off the old belt that were now gone. I said to him, “After about a hundred miles of driving, check the belt tension again. You may need to re-tighten it a little.” With that done, I walked home smiling, knowing my mornings would be a little more peaceful from now on.

'Belts are a Cinch' has no comments

Be the first to comment this post!