by Paul Dico

My love affair with Triumph sports cars began my junior year in high school, 1978. I have been an auto enthusiast since my father owned an AMC JEEP dealership in the early 1970s. I would ride my bike to the dealership after school. My father wanted me to understand everything, one department at a time. My first year I was introduced to the parts department, learning cataloging and ordering. The second year, my father had built a new body shop, and I was taught paint and bodywork from a very talented individual, Tony Cardenas. His technique and skill were unmatched. I was 14 years old and had no idea I was already on my career path. Unfortunately, my father passed away suddenly, and the franchise was taken over by the factory.

In my last two years of high school, I attended autoshop. It was the first hour class and I made sure I was present. I became close friends with Andy Corra, and I remember when he bought his car “Trudy.” Andy and I lived in the same housing division, and although he tried to tune that TR4, he benefitted from my time in shop class. My teacher owned a TR4, and I made friends with a guy who owned an auto parts store. Rebuilding Andy’s engine became my school project.

Senior year, I was infatuated with Chevy Hot Rods. A guy in my grade had a ’66 Nova SS but lost his license due to speeding tickets and was forced to sell the car. I had a deal with him to buy it, but when I went to confirm he said, “Sorry man, I sold it to my neighbor last night.” Then he said,

“You like those Triumphs, don’t you? Come on by my house Friday night. My dad has a Triumph TR3 he wants to sell.” I arrived to find a partially disassembled TR3 and a deal was made. I still own this car. I’ve been restoring it for several years, treating it like a museum piece. I hope to have the painstaking restoration finished this year. But that’s another story.

Andy’s Triumph went through three configurations. The original Trudy was a very rusty body with a Lucas wiring nightmare. TrudyToo was a better body but not very complete. It was a TR250 shell with a TR4 engine cobbled in it. Andy’s path and mine eventually parted when he veered to college and I joined the automotive trade. But when winter set in, and I had built a 70 VW Bug with a flawless drivetrain, Andy knew this and approached me with an offer to trade: his TR for my Bug. Done deal. Thus the story of my TR250 begins.

I stored TrudyToo until the mid-80s when I bought a TR250 parts car to put it all back together. I began with the frame, sandblasted and painted it after reinforcing the troublesome spots of the rear diff mounts and front suspension points. I had acquired American Racing Mag wheels and a surrey top in trade for body and paint work. I finished the car in 1987 after purchasing a third 250 for a few small bits I needed to complete it.

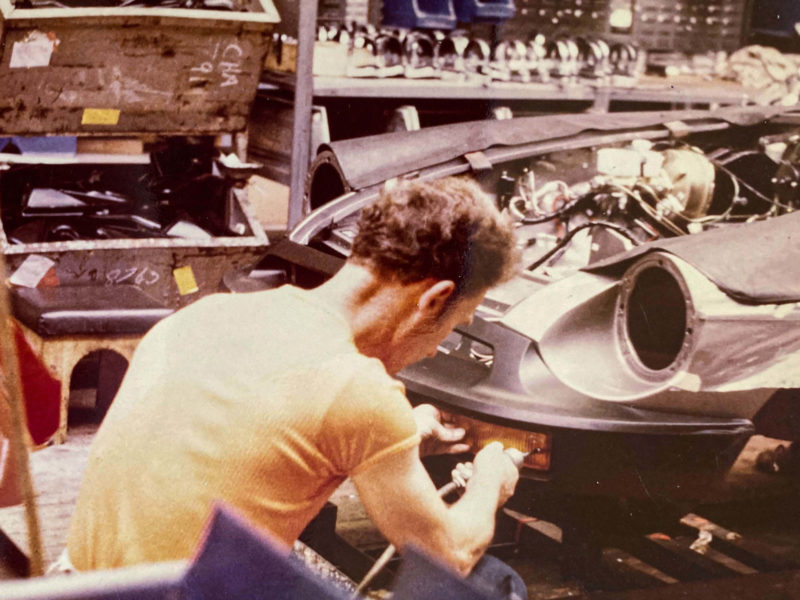

I had grown quite a following by British Car Owners who admired my passion for quality and aim for perfection. This drive is part of who I am, but it was also learned from others. The most memorable bodymen I worked with were two deaf guys and a man from Poland. Truly amazing men who each had different specialties in the field. They were “The Old Guys” of the time. Proper metal finishing techniques became the new passion for me as I was already a seasoned painter. Though as I continued to paint, I found it very important to keep up with the ever-changing advances in chemistry. During my career as a painter, I painted at least 100 British cars and many other makes, too. Each one was color sanded and polished to perfection before I finished. If I saw flaws, I fixed them—and I have an eye for seeing blunders.

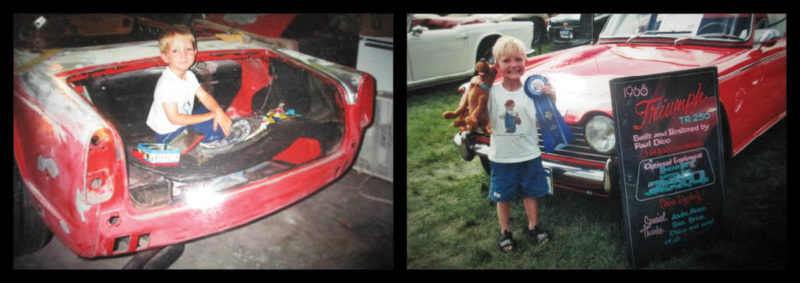

After the TR250’s restoration, I put it to good use. I have driven this car across the country twice, and it has been to three national Triumph conventions. It’s gathered a room full of awards. The original refinish I did on the car lasted about ten years before I took it all apart for the second respray in 1998. Technology advanced a lot in those ten years. This car looks as amazing now as it did in ’98. The most current accomplishment on it is the restoration of the aluminum surrey top center section I completed last summer. I restored the top and spent a painstaking 50 hours metal finishing it to perfection. No Bondo at all. The suede headliner is far from original material, but I like it. After driving the car with full surrey top on, I never want to take it off!

This car has been an important part of my journey in life. I’ve done 90% of the work myself—built not bought. I need to thank Paul Dierschow at Sports Car Craftsmen in Arvada, Colorado, and Juan Arce of Upholstery by Juan for their contributions. These two individuals are truly the best in the business. Also, to Andy Corra and Dale Wil for their support and friendship over the years.

As my career as a tech wound down in the late 90s, I then became a collision shop manager. I still did a few classic car projects a year for select individuals.

I’m that “Old Guy” now. It’s flattering when our painter asks me for help or advice on something. I still teach the young guys a few things. With our newest hire at work, a 26-year-old young man who is an amazing tech, I had to ask him if he knew the torch technique to repair hail damage. He replied with “not really,” and I told him he’s gonna learn it from this old man. It was my honor to teach him. Very simple technique really: you heat the top of the panel, slowly in a circular motion, around the dent. The heat causes the dent to rise. You bring it up slightly higher than it should be. While it is still hot, use a small sanding block with 220 wet sand paper and go over the dent a few times with cold water, and it will shrink it back to its original state. All that is required after that is a good heavy primer and that’s it. Same process on aluminum, just less heat is needed. I learned variations of this from three old guys and the last one had the technique I still use today. This took lots of practice, and I admit I ruined a few hoods learning. It’s all about the right heat on the torch. Smaller dents require less, larger dents a little hotter. This method of heating and shrinking metal is used in any basic panel repair. It requires patience beyond belief.

I never attended a school for my trade—not to say schools are a bad thing—real-time experience was best for me. I have loved my career choice and wouldn’t have changed it for anything. Makes me happy to see these younger guys I work with now with the same passion. I welcome any questions or requests for advice from anyone in the industry that I can help. MM

'Boomer Drive II TrudyToo is Reborn a TR250' has no comments

Be the first to comment this post!