One night as I was watching Letterman’s “Stupid Pet Tricks” and reading an old Peter Egan article “Speed Secrets of the Ultra Slow.” I was inspired and Stupid Sprite Tricks was born.

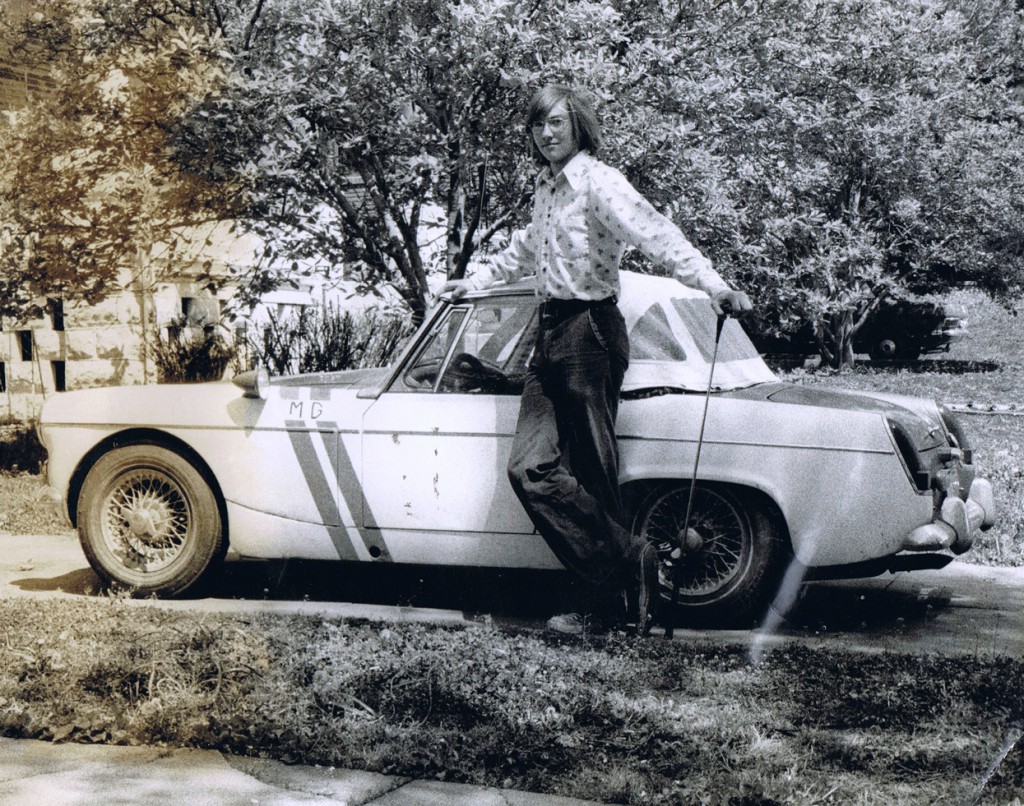

Jeff and his first Midget from 1973. “The car was painted like an old Pete Brock BRE Datsun race car and was mostly bondo and rust under the paint. This car started a 40 year love for British cars, made some great memories and taught me a lot about the right (and WRONG) way to work on a car.”

These stories are dedicated to the things we and others have inflicted on our British cars.

“What fools these mechanics be!”

– William Shakespeare (sort of)

———-

One very cold winter I replaced the head on my 68 Sprite. Work complete, I fired it up. Backfire, low power, you name it the symptoms were there. I checked everything( I thought) two or three times and finally called a friend, who took one look and switched the numbers two and three plug wires.

———-

I was called to help a friend track some electrical gremlins in a Bugeye. Thank goodness someone had taken the time to completely rewire the car. Entirely with yellow wire…

———-

About three years ago I took my 67 Midget out of storage. The car had been running fine about a year before, so I filled it with gas and started driving it. The car ran fine, except when I took a sharp or prolonged left turn. The car would simply die. No sputter, no fade out, just…nothing. The car would restart immediately after stopping with a quick turn of the key. I checked the connections to the distributor and coil, suspecting a broken or loose wire—no problems there—but the car still died. I checked the connections to the fuel pump—they were okay too. Float bowls, what else? I was stumped. After about the tenth time this happened, I decided not to re-start the car, but to get out and troubleshoot the problem right there on the side of the road. When I raised the hood and started looking for problems, my eyes were drawn to the distributor, sitting up higher than I remembered it! It seems at some point I had set the timing, and not tightened the clamp. On a hard left, centrifugal force would pull the distributor off the drive dog, and as soon as the distributor stopped, so would the engine. When the key was turned, gravity would do its magic and pull the distributor back down onto the drive as soon as they were properly lined up. Timing hadn’t been changing because there is only one way the distributor can engage the drive, and the rigid metal vacuum line held it in the proper position.

———-

Same car, three years later. I had rebuilt a spare 1275cc block, trying to be careful (I hadn’t done this in over twenty years), but trying to get more performance. (.060 over pistons, Kent 276 cam, reshaped combustion chambers, modified carbs—in short, the Bible according to Vizard) The idle was a little rough, (the cam you know) but it revved well, and only smoked a little, (rings not bedded in yet?), but I had the nagging suspicion all wasn’t quit right. What could it be, the engine was getting more miles on it, but the smoke wouldn’t subside. Was the mixture too rich off idle, after all I was running modified carbs with different needles and dashpot springs, or had I screwed up horribly when I modified the head? The number three cylinder seemed to be the culprit. I had damaged a ring when I put that piston in, but I had replaced it, and couldn’t see any signs of scoring on the cylinder wall. A compression check showed all cylinders within 5-lbs at 190-195. What to check next? Well the oil pressure was high, 80-lbs-plus when it started. Maybe I didn’t need that high performance pump after all, and it was forcing too much oil into the rocker shaft, and it was getting past the valve seals? I didn’t want to tear out the pump, so I pulled the starter, and installed some shims on the oil pressure relief valve, and dropped about 10 lbs. of pressure, but it still smoked! ARGH, WHAT HAD I DONE WRONG?!! Last Sunday I pulled the distributor cap off my brand new, less than 500 miles on it, trick Aldon performance distributor. Gee, I said why does the number three electrode look so brown? On closer examination, I found that the tip of the electrode was covered in brown plastic (plastic which was of the same material as the distributor cap), with only the thinnest sliver of metal on one edge exposed. I flicked the plastic off with my fingertip, and my problems went away. Apparently when the electrode had been inserted in the cap, there was a little layer of plastic in the base of the hole, and this stuck to the tip of the electrode, the thin sliver of exposed metal allowed some spark, but not enough for complete combustion. Always look for the simple things first.

———-

About two years ago my friend John called me to come over and look at the suspension of his Bugeye. The car had been apart for while, and when he tried to connect the tie rods, toe and camber were not to be believed. Several friends had already been over, and had left defeated. I looked at it for about half an hour, when that big cartoon light bulb appeared above my head, and I said, John, your trunnions are inside out, flip em around, and you’ll be OK.

———-

Back in about 1976 I bought a nice 68 Sprite for $1800, from a friend named Richard. He used that money plus $500 more to buy an E-type convertible for $2300 that “just didn’t move; something must be wrong with the engine.” The throttle linkage was messed up only allowing about 1/3rd throttle. Oh well, the Sprite was a good buy, right?

———-

I went to look at a 69 Sprite and when I got to the house the owner was nowhere to be found. I started looking over the car, and it was weird. Three windshield wipers, 69 dash, but a roadster removable top??? I returned with my friend Richard, and we both stood and stared for a few minutes, then he laid down on his back and looked underneath the car and spotted the weld lines. Someone had taken the good halves of a wrecked 69 and a wrecked 66 and made a compete car. We didn’t make an offer.

———-

Jeff’s son Gavin with the Bugeye they are restoring together. They are the 2nd owners, the original owner parked it 1973 and it hadn’t moved since.

I was trying to tune a 68 Sprite, and couldn’t get it to idle under 1300 rpm. I checked for intake leaks, and almost everything else. What I finally found was that the nuts on either end of the throttle shaft had been screwed out to the limit, keeping the throttle from closing that last couple of degrees when the throttle screws were loosened.

———-

My first Midget, a 67, would occasionally idle rough and spew black smoke. Knowing just enough to be dangerous, a figured out it had something to do with the jets sticking in the down position. WD-40, the mechanics friend, helped them slide back up for about 15 minutes,after each application. It was months later that I finally got around to reading that part of the manual about centering the jets.

———-

About 7 years ago I bought a rust free 67 Midget, one of the reasons it was being sold was “because the heater just can’t handle Nebraska winters.” After purchasing the car, I found that the lower radiator hose had no elbow for the heater return hose, and the outlet off the heater core had been routed alongside the engine and plugged. The car also had problems on acceleration, which I traced to a dashpot spring that would have been better suited closing a screen door.

———-

While installing a Datsun 5-speed in my Midget, I just couldn’t get the dang clutch working right. Clutch in, grind, grind, grind. Take some slack out of the system, try again, grind, grind, grind. Take out more slack—you guessed it. Pull the engine, take it all apart and find the cone on the clutch disc is worn, as well as the surface it would contact on the pressure plate! I had been going over center, and should have been putting slack back into the system.

By Jeff Lemon

'Stupid Sprite Tricks' have 5 comments

June 8, 2012 @ 8:43 am Rennie Bryant

We had been campaining a Bugeye in SCCA in H prod. in the Fla. region. We won the regional championship and were invited to the SARRC runnoffs in Savanna a at Robeling Road for that championship. SO we decided that we had been running that motor all season and we should “freshen it up” for the big race. Our engine builder did his magic,we put it back in the car and off we went.

Qualifed on the pole in class. 1st lap before the 1st turn, Ka BLAMMO!!! The largest 948 explosion ever seen. It blew the center main web right out of the block with the main bearing, the center of the crank and number 2 & 3 rods still attached and spinning freely. Needles to say our day was done, made a nice trophy though.

” I spent the better part of my misspent youth turning perfectly good Sprite engines into fragmentation grenades”

Peter Egan

June 8, 2012 @ 2:10 pm Quinton Brantley

When I was in High School I was restoring a ’68 TR 250 while driving it to school. My friends like the car but always gave me a hard time because of the flat black primer color and the lack of evident progress and my suspect mechanical skills. They were always telling me that some piece had fallen of in the parking lot or that there was a massive leak of some kind of liquid. You get the picture. The best part was the car ran great with the exception of the occasional gearbox rebuild. So I decided to take it on a trip to Road Atlanta, for the IMSA race, from Raleigh NC. All of the sudden, it was as if the car had determined that it was not going to run about 2 hours outside of Raleigh. Misfiring then stalling. We pulled off the interstate looked over all that could have caused the issue, and everything was in place. Got back in the car, tried to start it and it fired right up. This happened with no consistency six more times to Road Atlanta. On the last stop I noticed that the fuel filter did not have any fuel in it? It had a full tank of gas by the gauge and by inspection of the inside of the tank through the really cool Magnetic non locking Official Sebring Race style full filler! As I was looking into the tank, something caught my eye…there was something in the tank which turned out to be a #2 Pencil of one of my HS Buds putting my mechanical skill to the test. Turns out every once in a while the pencil would get stuck in the fuel line in the tank and starve the engine and after awhile pop out! And that’s what friends are for!

June 9, 2012 @ 8:16 am David Schneider

Back in 1969 my daily driver was a 58 Healey 100-6. On a date with a really hot chick, she noticed that the fuel gauge was close to empty. Well no self respecting young stud would want to run around with too much gas. After all it would eliminate the opportunity running out of gas would afford with a hot chick in the passenger seat. Acting nonchalant, I told her that there was “enough gas to get to South Bend and back”. Immidiately the engine quit from fuel starvation. She still teases me about that whenever any discussion occurs of fuel availabity versus distance to a gas station. You would think that after 41 years of marriage she would cut me some slack. Yes I still have the Healey. Yes she won’t let me forget it. Yes she still has the magic (the girl).

So I am spending an unreasonable amount to totally restore the Healey. When I again drive the hot chick on a date in it, I am purposly going to drive back to that spot (about 80 miles from our home now) and let her have her fun. Oh she is going to enjoy repeating my fateful words, she has a great sense of humor.

Sometimes we keep things a long time just because we enjoy them so much.

June 9, 2012 @ 5:59 pm Carrol AnneThompson

I bought brand new prototools with swivels to R n’ R the starter, before redoing the interior, and finding the tunnel access for doing that “job.”

Also had/have problems with the ‘Princess of Darkness,’ where heat caused sudden power loss. I finally started the traditional ‘wire wiggle ritual,’ and actually discovered the coil, installed upside down, on the inside of the fender, didn’t have the tightest clip attachment, and the rubber cap would begin to release after a certain amount of heat, slowly enough, that a simple rest would contract the rubber just enough to make contact, and it was just not as common an occurance in cooler temps. Why was it installed inverted?

Short wire ?? ;B

And another, brake lines buried in dirt and grease from a former leaking seal, pre purchase, cover the brakes lines under the frame, so when drilling holes for the new seats, of course I found them, er it, I had managed to miss it doing the other side .. repaired well, NO problems, of course I’ll replace it.

Had a taxi driver “help” me jump start my tempermental roadster, at the bottom of an underground parking garage, and when I wasn’t looking, yep, he reversed the leads, eventually starting it after my insistance, and his realization, and now I have ‘untraceable’ electrical issues. I’m about to get a new voltage regulator, and I’ve found an old area of melted wires, where contact appearts to be, it’s always something. . .

How do you tell if you need springboxes, or 1/4 elipticals ??

June 10, 2012 @ 5:28 am Gryf Ketcherside

The first time I rebuilt the Zenith Stromberg carburetor in my ’78 Midget, the thought occurred to me that the set screw that retains the metering needle in the air piston and keeps the needle from rotating during mixture adjustment surely shouldn’t be tightened all the way, because that would lock the needle holder and prevent it from moving up and down during adjustment. So when I reassembled things, I ran the screw in just far enough to engage the slot in the needle holder. Shortly thereafter, I was proceeding merrily along a local highway when the engine died. I coasted off into a handy side road, popped the bonnet, and started investigating. After a bit of fiddling about, I removed the air filter and stuck a finger into the carb to check for piston movement, only to find the needle had dropped out of the piston and was resting in the jet. That was easily fixed, and it was then I learned that the metering needle set screw has a spring-loaded tip, and that it’s a good idea to snug the screw up until it’s tight.