By Lawrie Alexander

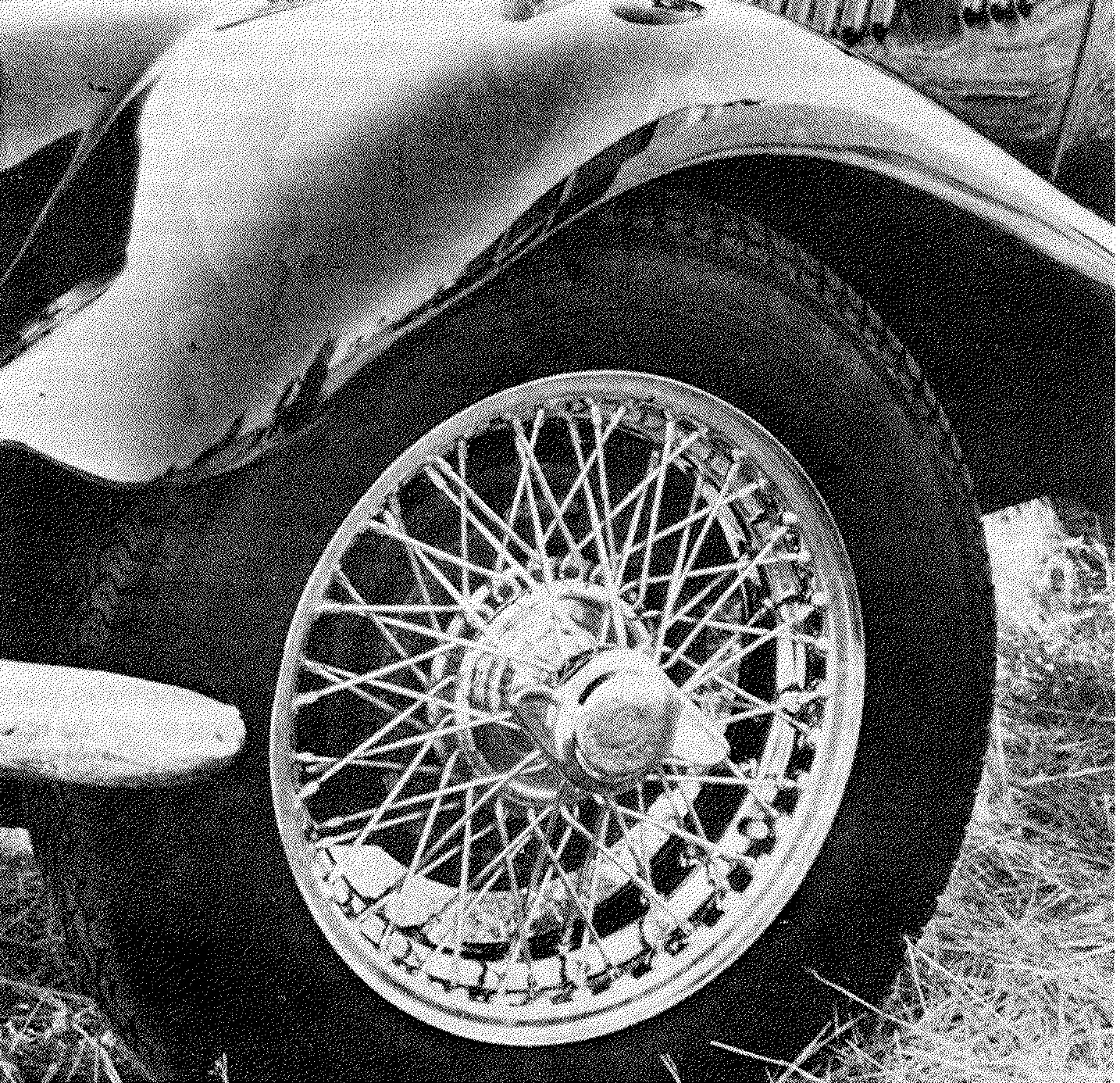

One of the less popular aspects of wire wheels is that they tend to go ‘out-of-tune’ and need occasional straightening (or ‘truing’). This is caused by the spokes stretching and by the spoke holes wearing, both of which result in a change in spoke tension; This causes the rim to run out-of-round.

One of the less popular aspects of wire wheels is that they tend to go ‘out-of-tune’ and need occasional straightening (or ‘truing’). This is caused by the spokes stretching and by the spoke holes wearing, both of which result in a change in spoke tension; This causes the rim to run out-of-round.

Consider that the weight of the car is suspended on the few spokes that are uppermost in each wheel and that they are constantly moving into and out of this weight-bearing position when the car is moving. Add side loads from cornering and you can understand the stresses that cause the spokes to stretch and move around.

A wheel which is tuned to run true may be kept this way by monthly checking of spoke tension. Run a pencil around the spokes and note whether any make a sound which is markedly lower in pitch than the others. Tighten these flat ones with Moss spoke wrench (#385-800) and you will maintain the wheel in a nice, round condition.

OLD WHEELS

If your wheels have not been trued for some time, simply tightening the flat spokes will not necessarily make them run true. You might just tighten them permanently into their buckled condition! An old wheel should be properly trued to eliminate radial and lateral runout before being put on the monthly maintenance program.

NEW WHEELS

When the wheels are assembled at the factory, they are laced so as to be within factory tolerance for radial and lateral runout. Since the hubs, rims and spokes are new, this tolerance can be achieved without the spokes necessarily being tensioned evenly! Result? When a new wheel is subjected to a load, it may go slightly out of round. Even when the spoke tension is correct, some settling will occur during the first couple of hundred miles, as the spokes and nipples bed into their seats. A good practice with new wheels, therefore is:

A) Check spoke tension before mounting new tires. Tighten any loose spokes, check for excessive runout and remedy by tightening appropriate spokes.

B) Drive gently on new wheels at first, allowing them to settle in without severe stress.

C) Re-check spoke tension and runout after new wheels have been used for a couple of hundred miles or so. Following this procedure, and remembering to clean and re-grease the hub splines every 4-6 months, will give you years of trouble-free life from your wire wheels.

'Tech Tip – About Wire Wheels' has 1 comment

February 22, 2022 @ 4:08 pm James moore

What do you use to hold the spoke from turning while tightening the nipple?