A look inside Moss Motors

Imagine having a garage with a parts bin that is computerized, cross-referenced, and equipped with a staff of skilled individuals whose job it is to fetch the particular piece you need. Multiply this image until its scale matches that of a modern supermarket, and you have the Moss Motors warehouse.

“We actually export a large number of parts to the UK,” says Craig Cody, call center manager for Moss Motors. “About 10 o’clock, this place will be humming.”

The order gets printed in the warehouse, where a parts puller will assemble the items. The puller tracks down each part and checks it off on the list.

Comprised of two levels and 60,000 sq. ft., the warehouse is filled with a seemingly endless array of British sports car components. There are shelves with TR6 transmission tunnels, Healey camshafts, MG doorstops, and even a box filled with rubber seat diaphragms, as if seat diaphragms were as common as flat washers. For certain models, the parts inventory is so extensive that a person could construct a brand new car from parts ordered over the phone.

The warehouse is orderly and all business. It is like a library filled with steel and possibility rather than paper and ideas. “We have written a computer program that looks at our monthly flow of inventory.” Cody says. “We use that information to arrange the stocking. Parts that sell often get put in the front. This way we eliminate steps for the parts pullers.”

The checker makes sure the correct parts have been pulled. He also looks for strange orders that could denote an error. Things like an order for 500 head gaskets or a part that is supposed to be shipped to the state of CZ.

It is easy to wonder where all the parts come from. After all, most of the cars Moss supplies components for ceased to be manufactured 20 years ago. “We belong to something called the British Motor Heritage Trust,” Cody says. “They will provide original drawings and specs for out-of-production parts. If the tooling is available, they will allow access to that as well.” It is a system that works well if the tooling or specs are available, but sometimes the only reference is an original part. Original parts are kept in a special lockup at Moss. “If we can’t get the drawings for a part, then we have an engineering department that will reverse-engineer [the part],” Cody says. “We try to match materials to the original as best we can, but sometimes the manufacturing processes used are so archaic that the only way we can reproduce an item is to go overseas.”

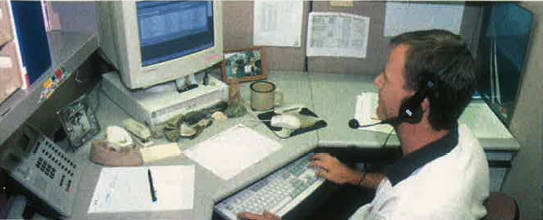

If the warehouse is the stomach of Moss, then the call center is the brain. There is a current of muffled tension that runs through the cubicle-covered space. On the walls are monochrome representations of various roadsters. A neon Austin-Healey sign glows red. One gets the urge to pop into the door below for a pint. On the wall directly opposite the sign, however, is a television monitor that displays the status of all the call center’s sales staff. It provides a real-time representation of the room’s activity. If an operator is talking with a customer, the screen displays it. If an operator is available to take a call, that is also displayed. “That monitor,” Cody says, pointing to the Cyclops above, “is a copy of what I have here on my screen. The system is automated. The computer recognizes the prefix a customer has dialed and automatically directs them to the appropriate sales person.”

Once the order has been pulled and checked, it goes to the packer. Here the items are placed in boxes and packed for shipment. If an item is large, it will be marked as a C-pull and will be grabbed at this stage.

When the system is operating at standard levels of efficiency, it is a marvel of quickness. “A typical order will take 20 minutes from the time the customer hangs up to the product being ready for the courier,” Cody says. This sounds too incredible to believe, but Cody does not balk at a request to track an order through the system. It is a process that turns out to be so simple that it almost could be termed a nonevent. This isn’t to say that it’s not an impressive feat. It’s just that, like a skilled race car driver, these professionals are so good at their task, it looks easy.

Many British car manufacturers were ruined by a lack of efficiency. It is interesting to note that efficiency has allowed Moss, a company that began in a small garage, to not only revitalize a 20-year-old industry, but to reverse the flow of product as well. The irony is that modern, computerized technology allows us to get something labeled “Lucas” shipped to our homes in one day. It is a system that keeps the customers happy. Apparently, even the English are buying.

'Den of Efficiency' has no comments

Be the first to comment this post!