Whew! Let’s do something a little bit less ambitious this time. How about a new fuel pump? Of course, you don’t just replace the pump for the hell of it. The obvious scenario is that the damn thing won’t pee a drop, so you swap it for a new one and bada-bing, it’s a done deal. Unfortunately, that is not usually the way things go.

What really happens is that at the least opportune time, the car sputters and dies for no apparent reason, then mysteriously runs again, making you wonder what the heck is going on! Not to worry, you don’t really have to guess about the condition of that old pump. Don’t try disconnecting the fuel line from the carbs and seeing how far the gas will shoot when you crank the engine. Instead, on your next trip to Harbor Freight, purchase a combination vacuum and fuel pump tester. Now not only can you check the manifold vacuum, but you can test the fuel pump for proper operation. A really clever fellow would test the pressure on all his LBCs just to get an idea of what to expect.

What really happens is that at the least opportune time, the car sputters and dies for no apparent reason, then mysteriously runs again, making you wonder what the heck is going on! Not to worry, you don’t really have to guess about the condition of that old pump. Don’t try disconnecting the fuel line from the carbs and seeing how far the gas will shoot when you crank the engine. Instead, on your next trip to Harbor Freight, purchase a combination vacuum and fuel pump tester. Now not only can you check the manifold vacuum, but you can test the fuel pump for proper operation. A really clever fellow would test the pressure on all his LBCs just to get an idea of what to expect.

Connect the gauge to the output of the pump with the input still coming from the tank. Crank the engine for five seconds or for an electric pump; turn on the ignition for a few seconds, listening for the pump to reach full pressure. On original SU pumps the unit will stop clicking when the pressure has built up, while on most aftermarket electric pumps, the sound and frequency will diminish. Shut everything off and look at the gauge. It should read between 2 and 4 PSI, but more importantly, the pressure should hold indefinitely. Too much pressure can cause the float bowl to overflow, causing the engine to flood and gasoline to drip all over that hot exhaust manifold. Harbor Freight also sells fire extinguishers!

Truth is, many fuel delivery problems are not the fault of the pump at all. Replacing all the lines is a sure fire (there’s that word again) way to insure that all the walking you do is with Fido. Crud in the gas tank often accumulates in the fuel line, especially on Triumphs with fuel lines coming from the bottom of the tank. Usually, the pump has a screen in it, or the lines at the carbs (SU) have thimble like sieves. If you were to look into the bottom of your float bowls, you would see that the OE filters don’t keep all the dirt out of the carbs. If junk gets past these filters, the check valve in the float bowl will malfunction, causing the car to die or even worse, the bowl to overflow. To prevent this situation, a clear disposable fuel filter (Fram G2) should be installed as close to the tank as possible. Installing a filter under the bonnet right before the carbs is convenient, but not entirely effective. Soon after adding the new filter, you will almost certainly notice a build up of silt in the filter. This stuff has been running through your lines for years!

On MGs and Austin-Healeys the line comes from the top of the tank, greatly reducing the amount of silt getting into the system. Unfortunately, sometimes there is a screen in the tank which can become clogged resulting in a total lack of fuel delivery, especially if a tank sealer product has been used. You should be able to blow into the fuel line where it leaves the tank (with the tank vented) without getting red-faced. A plugged up vent can cause lots of trouble; a vacuum will be created and eventually the pump will be unable to suck any gas. On modern cars you expect to hear the rush of air when removing the gas cap, but never on a vintage vehicle. Some old cars have vented caps, while others have a vent line coming out the top. If your LBC is not stinking up the garage with fumes, the vent may not be working! About 1968, carbon canisters were added to some models to contain the fumes. That is a really nice touch that should not be removed in a misguided attempt to de-smog control the engine.

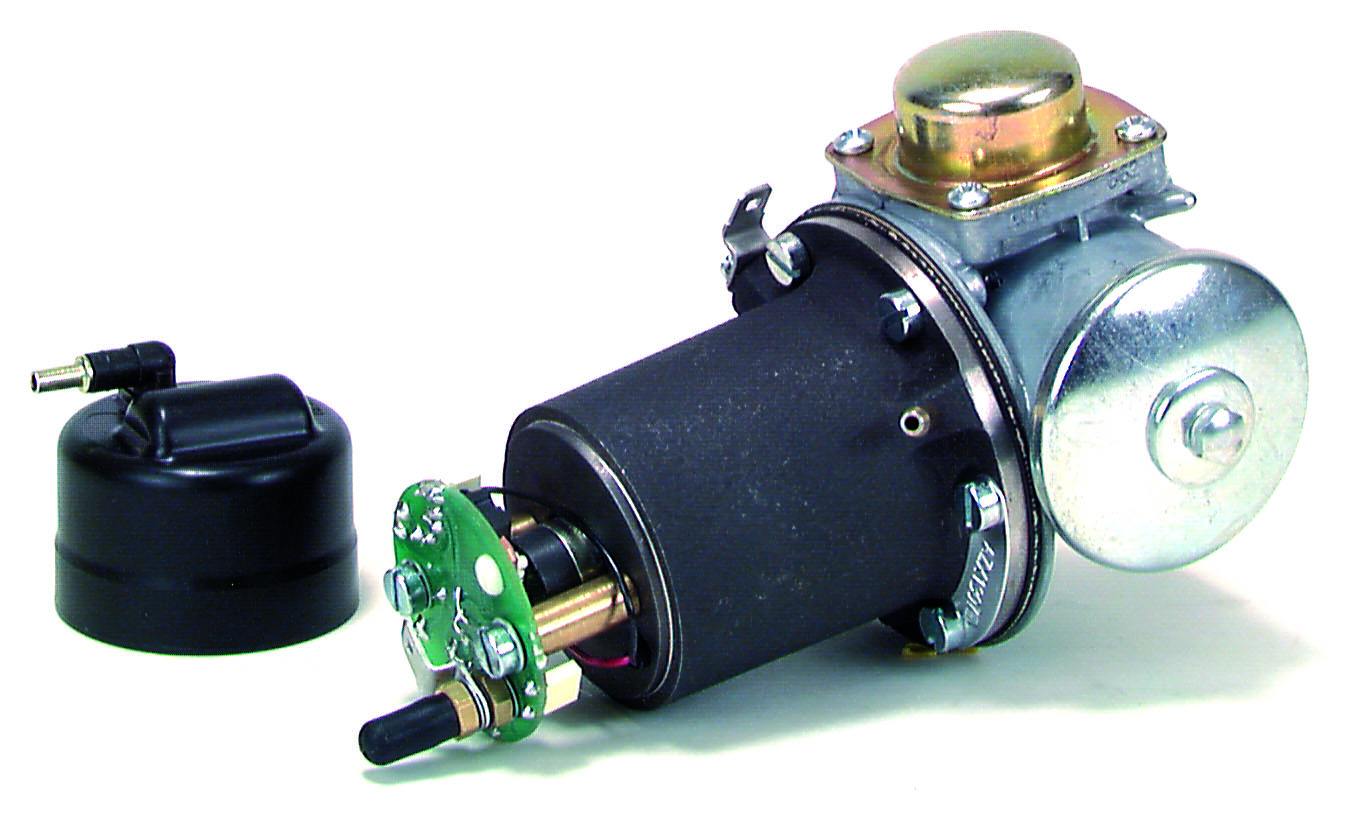

I don’t think that replacing the OE mechanical pump with an electric model is a particularly good idea, but replacing that old SU pump with a modern solid-state SU pump may be wise.

By Mike McPhail

Gulf Coast Austin-Healey Club

Hill Country Triumph Club

'Pint Size Project — Fuel Pump' have 4 comments

October 12, 2012 @ 10:11 am David DuBois

I must respectfully disagree with Mike’s suggestion of placing a filter between the fuel tank and the fuel pump when said pump is an electric (or all electronic SU fuel pump). As Mike stated, the filter in the SU fuel pump and in the tank are designed to trap the large stuff (rocks and small birds), but allow the very fine silt to pass through. By putting a modern, high efficiency filter in the line, the fine silt particles can completely block the filter, causing the SU pump to stall in a current on condition which, if the power is left on, will cause the pump to over heat and be damaged. For a full description of what kind of damage will be caused, see the article SU Fuel Pumps, Facts and Myths in the SU Fuel Pump Articles section of my web site at http://homepages.donobi.net/sufuelpumps/

If, on the other hand, you have a mechanical fuel pump or one of the after market electric pumps that use a bypass valve to establish the output pressure, you can safely put any kind of a filter you want in the line.

Cheers,

Dave

October 12, 2012 @ 11:44 am gIL

I wonder why MG installed a fuel filter at the factory?

February 22, 2013 @ 8:03 am mark

good idea to put extra filter on if we could but it would lower the pressure to much by having two filters ive tried it on a vivaro van

August 5, 2019 @ 12:45 pm Paul Wortmann

I have a new fuel pump part # 377-161, on it are 2 what look like vacuum line connections. What should I do with them?